Find a Reliable waterproof bag supplier in 5 minutes

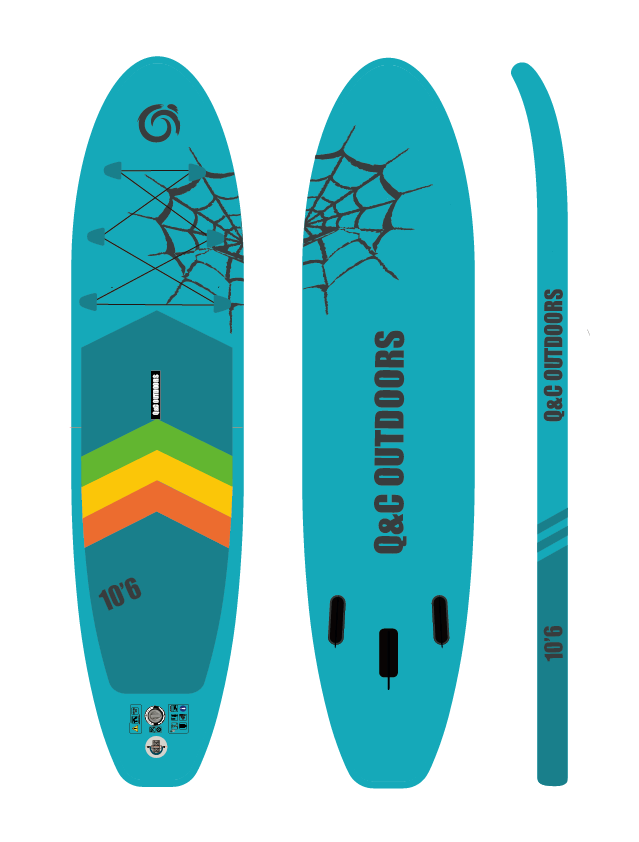

Are you facing with the complexities of communicating and organizing goods with A and B and C during the purchase process, trying to convince them to combine your goods into one container? Here is the one-stop purchase solution. We not only offer you paddle boards and accessories, we offer you the water sports must goods, dry bags. We have 80 workers, 15 sewing machines, 25 heat-press machines which specially focus on producing various of dry bags.

- professional designers always trying to develop new items

- Sample masters to make all kinds of designs into real bags

- Waterproof testing, loading testing in our lab or in the third party lab

- Over 800k waterproof bags are exported worldwide each year

Hot products according to our clients feedback

Below are some of our best selling items according to most of our buyers feedback. Acutally we have more choices for you, please contact us to talk about your detailed request.

swim buoy

fashion

dry bag

hold-all

dry bag

wet-dry

seperating BAG

SUP BACKPACK

swim buoy

waterproof

backpack

bucket

Top 3 dry bag materials

PVC & TPU

Most water sports dry bags in the market are made from PVC material, some is 250D PVC while others are thicker 500D PVC, depending on how big the bag is and what the bag is expected to hold. PVC is the cheapest dry bag material, but it is heavy and not environmentally friendly. TUP is a good replacement if you want it to be chemical free and lighter. But of course, TUP cost more.

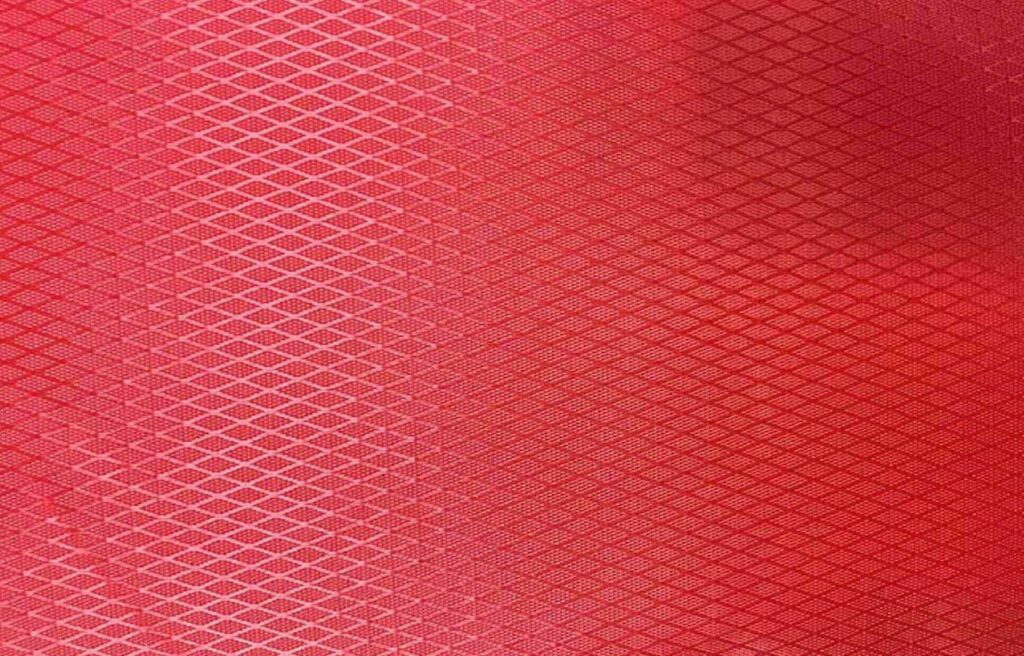

210T ripstop PVC/TPU coating

210T rip-stop with PVC or TPU coating is also a material that is used to make dry bag.This material is much softer and lighter. It is very easy to fold and carry and mainly used to make small dry bags or some stylish waterproof bags for everyday use.

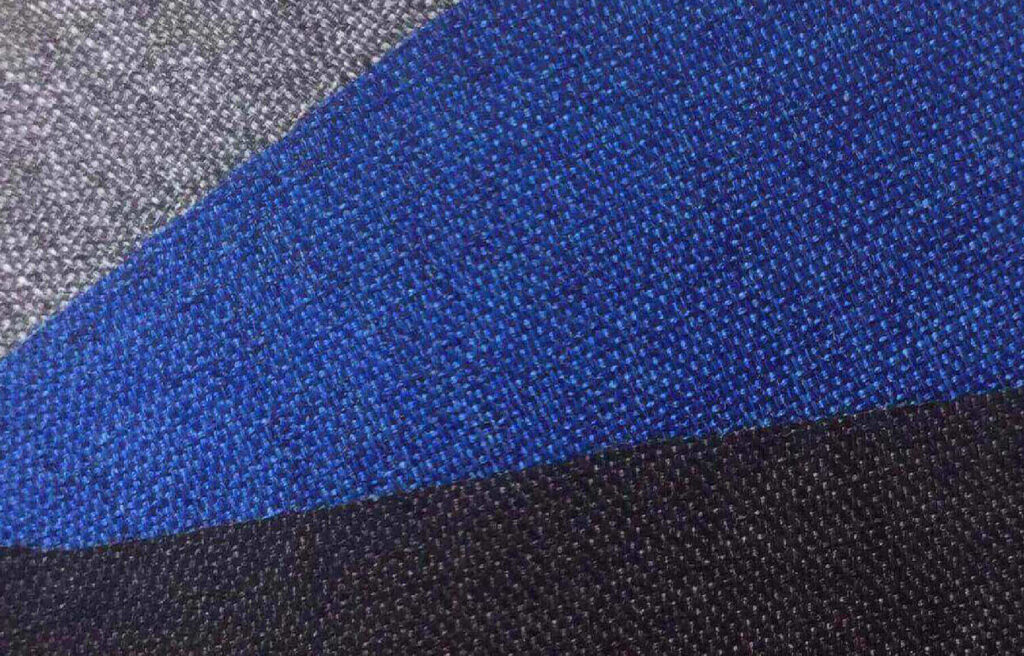

300D polyester PVC/TPU coating

The material of 300D polyester with PVC/TPU coating is normally made in two-tone colors. This dry bag material is also softer and lighter than PVC. Thanks to the fabric outside, this material is very durable and looks high-level, so it is mostly used to make stylish backpacks for men for everyday use, or or make some higher level dry bags.

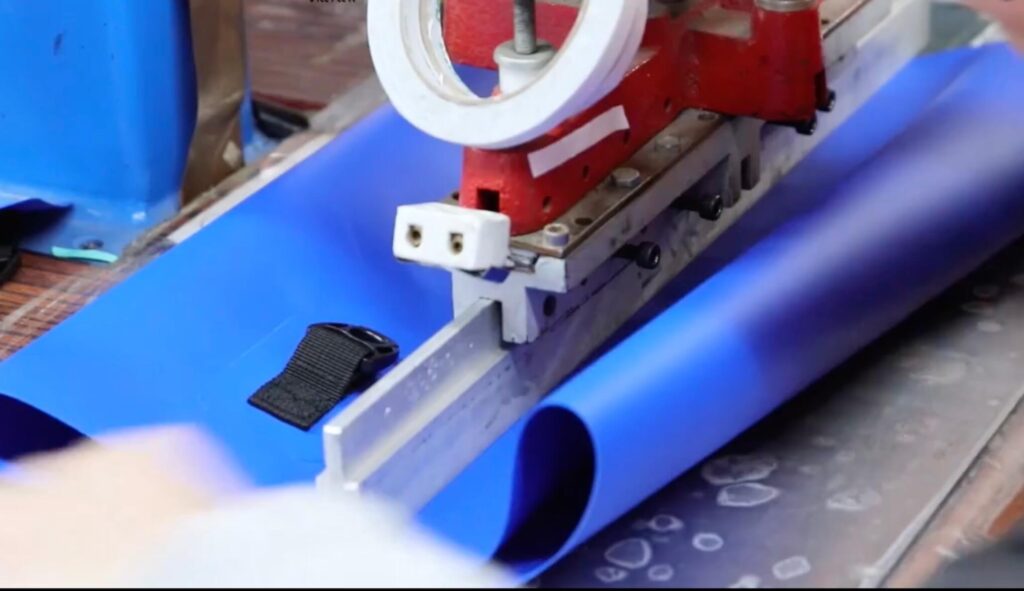

Our workshop display

Sew The Strap

Welding Handles

Hot pressing

Quality Checking

Cutting Material

Mass Goods

Sewing

Hot pressing

Sewing

Estimated manufacturing and shipping times

Making Samples

Step 1

Material Purchase

Step 2

Mass Production

Step 3

The production time depends on order Qty. It normally takes 10 to 20 days to finish the goods.

Sea Shipping

Step 4

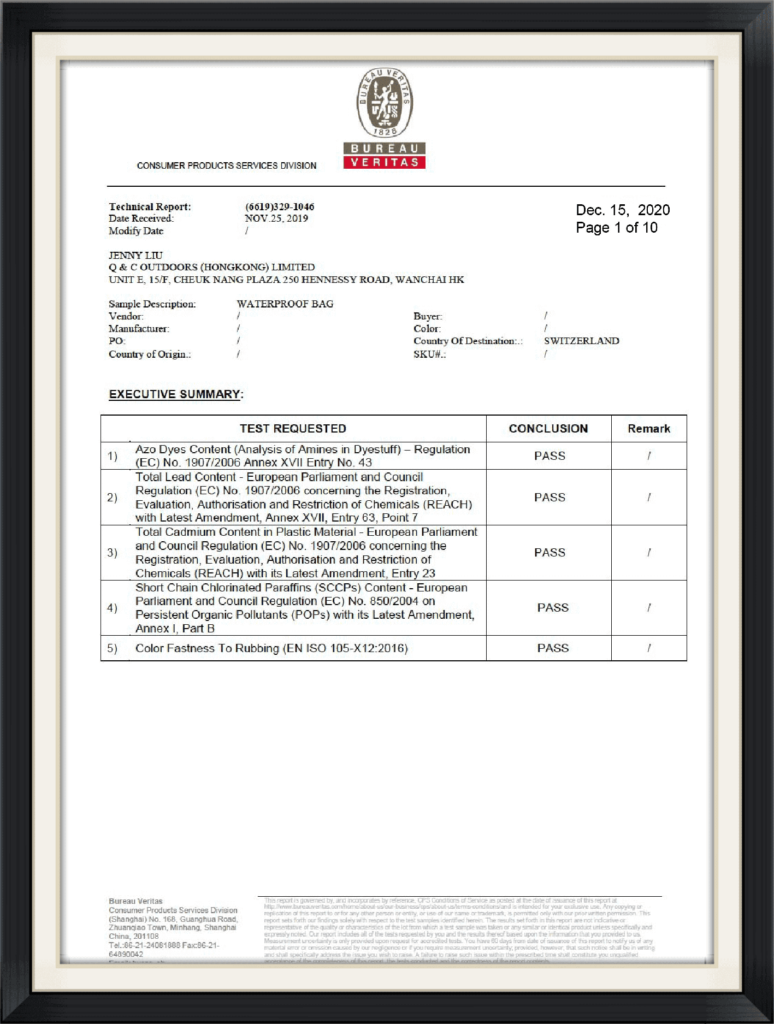

Third Party Test Report

CE TESTING REPORT

CHEMICAL TESTING REPORT