paddle board in single and double chambers

Looking for a reliable inflatable paddle board manufacturer?

Our factory has been focusing on producing Inflatable paddle boards for 8 years, which is why we’re among the leaders in this industry. We have a wide range of different boards, from all-round board to touring and racing board. Whether you need a single chamber or a double chamber, they are all available.

Based on long time’s experience and the high quality drop-stitch material, our boards are very stable and durable on both calm and white water. Our high product quality and two year’s warranty will solve all your after-sales problems. With the capacity of 1000pcs boards per day, timely shipping can be ensured.

We are happy to help you create an awesome design for your business. Our team can turn any idea into reality. Besides, our current designs are also available for your choice. Contact us by below button to talk about how our boards will benefit your business.

How to make an inflatable paddle board?

drop stitch material

Shape Cutting

Logo Printing

Make Air Chamber

24H Air Leaking Testing

Air Leaking Repairing

Glue The Second Layer

Add The EVA Mat

Add The Fins

What makes us special ?

ISUP is a purely hand-made product. During the passed 8 years, our technicians and workers have accumulated a wealth of experience. Our workers glue the drop stitch top and bottom together with no any bubbles, which ensures the low air leaking rate at the first step. Though, to be 100% sure, we inflated every board with 15PSI and left for 24 hours to test any possible air leakage before moving on to the next step. For those found to be leaking, we will apply soapy water one by one to detect the leaks and repair them at once. After the product is finished, we will have a professional inspector to check all the parts of the board before packing.

We offer below after-sales service

- 2 years refund if the air leaking is more than 2psi in 24 hours in normal tempreture around 20 degree.

- 1% free parts including paddles, bags, leashes and pumps to be shipped with mass goods

- HD Photo shot for your catalogue and website

- Packing design including color box and manual

Table Of Contents For This Page

The following content is a bit long, so I made this directory here to make it easier for you. You can jump right down by clicking on the corresponding image below!

Hot Products

single board vs fusion board

single chamber VS double chamber

Product Category Ratio

Purchasing process

Storage and maintenance

After-sales service

Frequently Asked Questions

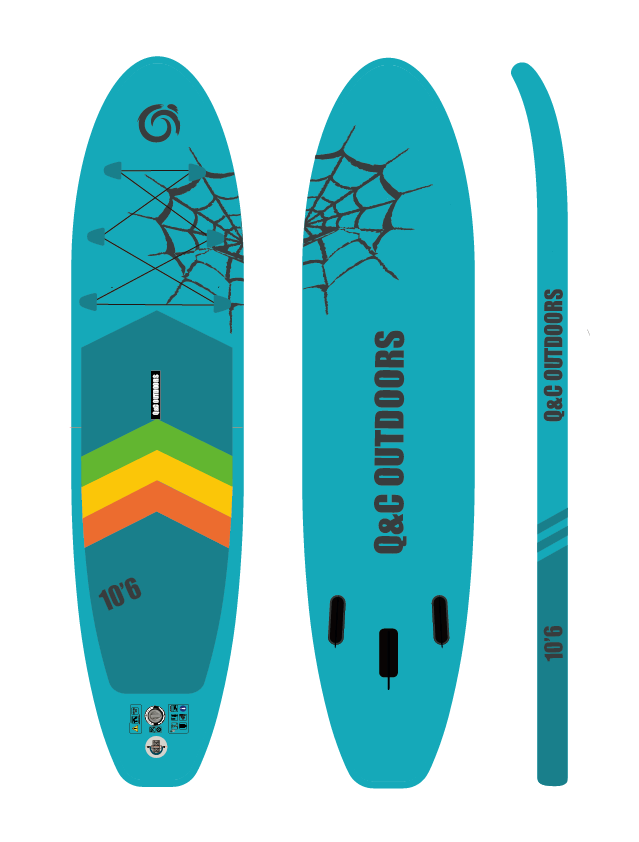

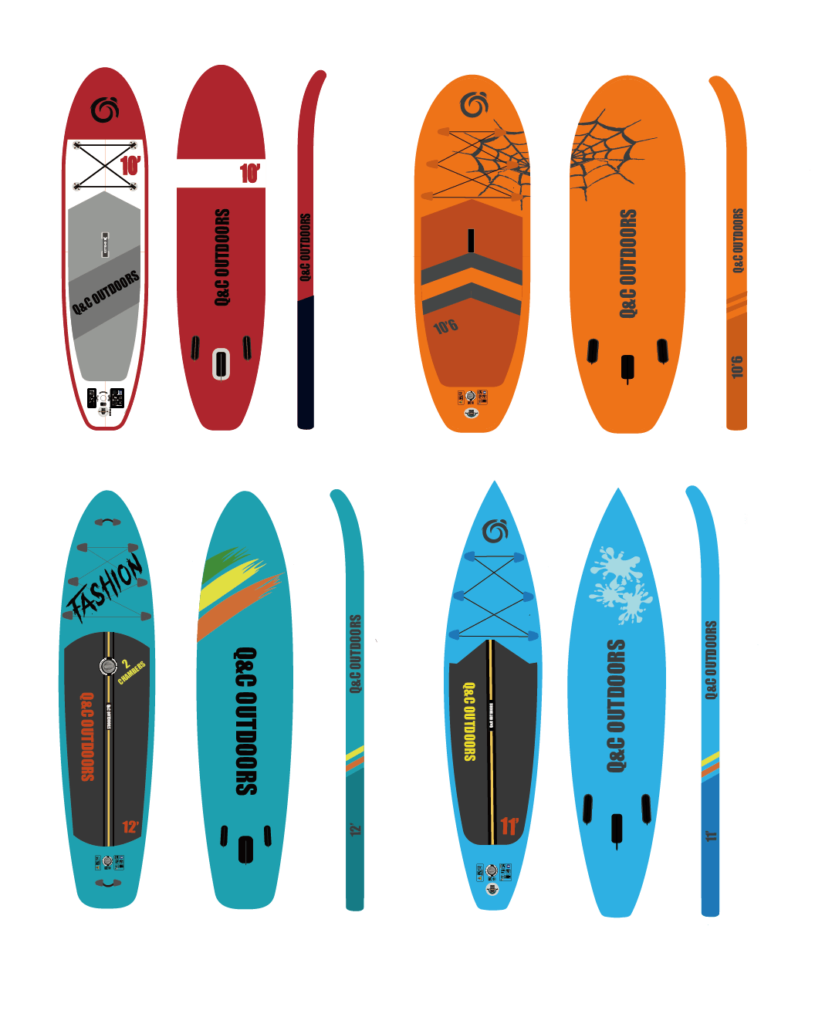

HOT PRODUCTS

Among the various paddleboards, our best-selling ones are 10’x30″x4″, 10’6×31”x6″, 11’x32″x6″. The 10’x30”x4″ board is targeted at youth and thin adults. The 10’6×31”x6″ one is the most sold size, this size is generally used for all-round boards, because it is suitable for most people’s height and weight, and this size also offers a smooth and stable paddling in most of the water conditions. The 11’x32”x 6″ board is also mostly an all-round board, the longer size offers more space. The target group of this board is mainly families, such as one adult with a child or with a pet.

single board VS Fusion board

For single board we have only the drop-stitch layer. The shortcoming of this board is that the maximum PSI cannot be too large, normally recommended 10PSI to 12PSI. Due to the low PSI, this board is not so rigid and stable. To strengthen it, people glued a second layer PVC onto the top and bottom side of the single-layer board to make it double layer, so it is more stable and can withstand greater air pressure. But this double layer board is complicated to make, and it is also especially heavy. To solve this problem, the technicians finally developed a new material, they laminated the second layer of PVC onto the drop-stitch material directly when producing it. The board made with this new material is called fusion board. And the max PSI for fusion board can be 20PSI, this offers us a lighter board which is also very hard and stable.

To put it in an exaggerated way, the difference between a single-layer board and a fusion board is like the difference between a balloon and a basketball.

One air chamber VS two air chambers

The majority of boards on the market today are still single-chamber boards, but in some EU countries,paddle boards must be made with double chambers according to the regulations. The point of the double chamber is that when the board breaks and leaks in an emergency situation, the second chamber in the middle will not be affected, thus ensuring the safety of the paddler. But in fact, most boards, especially the fusion board are all in very good quality, there’s very few chance that it will suddenly burst during the paddling as long as not cut by some sharp rocks or branches. So it depends on what kind of water you are paddling.

One more thing, the double air chamber board is much more expensive than single chamber one because of the complexity of production process.

What kind of board to order ?

Normally it depends on your market. While based on our experience, we recommend you below quantity.

For a 20’ container, it can load about 270pcs. You can order 90pcs in 10’x30”x4”/6″ for kids and youth with single material, 180pcs in 10’6×31”/32″x6” in fusion Material.

For a 40’ container, it normally loads 550pcs.You can order 100pcs in 10’x30”x4”/6″ for kids and youth in single material, 300pcs 10’6×31”x6” in fusion material, and 150pcs 11’x32”x6” in fusion material.

If your market is specially good for travel by paddling, you can also order some touring board with size longer than 12’

What is the order process?

As SUP is becoming more and more popular, people don’t just paddle in the summer , many people now also paddle in spring and autumn, and some even paddle in the winter as well. Based on the seasonality, we generally start the design and decide which sizes and styles to purchase from March to May, to make sample in June, to send out samples in June and get the final confirmation latest by end of August. Customers normally place orders from beginning of September to latest October. Winter is the peak season, It takes about 3 to 4 months for mass production. We start shipping out the goods from January to March. It normally takes 30 to 40 days for the shipping to Europe and US. The goods must arrive warehouse no later than middle April to catch the season. So please work out your schedule before the purchase.

Questions you might want to know

HOW LONG IS YOUR LEAD TIME?

It takes 45 to 60 days in low season from Apr. to Sep. And 60 to 90 days in peak season from Oct. to March.

Where is your drop stich material produced?

The drop stitch technology is now very mature in China. We buy our material from the largest drop stich factory in China.

What is your max PSI of yoru board?

For the fusion board, the max PSI is 25, and for a single board, the max is 18PSI, while to be safe, we normally mark 15PSI for the fusion board, while 15PSI for the single board.

Which port do you ship?

Our factory is located in North-East China, so we ship from Qingdao port.

Can you make SUP with very complex colorful design?

Yes, we have 4 machines which are specially for printing on the boards.

How many pieces can be loaded in a container?

Normally 280pcs in a 20′ container, 580pcs in a 40′ container, and 680pcs in a 40′ High container.

Can we buy the accessaries seperately?

Yes, we offer accessaries. You can order them with your boards together, or order separately.

HOW LONG IS YOUR warranty?

We offer one year warranty. While we will ship 1% of the order QTY free spare parts to you for handling the aftersales service.

Third Party Test Report

CE TESTING REPORT

CHEMICAL TESTING REPORT